Nano Fabrication Center

Nano Fabrication Center

RII Core Facilities Pilot Program - May 3, 2023 Deadline

The RII Core Facilities Pilot Program is designed to support three key types of activity within the RII-managed core facilities. Each CFPP proposal will be evaluated on scientific merit and feasibility, and should focus on one or more of the following activity types:

- The development of new methods or techniques that would extend the standard operating procedures and capabilities of RII-managed core facilities and potentially impact multiple UA researchers.

- The acquisition of preliminary data needed for extramural proposals. Successful projects will result in at least one new extramural research proposal.

- The technical training of students conducting research under existing extramural funding. Proposals to train students from traditionally marginalized groups will be given funding priority.

Most awards will be capped at approximately $10,000, although well-justified projects may be awarded funding above this level. It is required that CFPP proposals and their budgets be developed with the assistance of the relevant core facility manager(s). Proposals are due May 3, 2023 by 5pm. List of eligible facilities:

- Analytical and Biological Mass Spectrometry

- Flow Cytometry and Human Immune Monitoring Shared Resource (BD LSR, BD, FACSARIA, BD Canto)

- Functional Genomics Core

- Imaging Cores - Electron

- Imaging Cores - Optical

- Machining and Welding Center

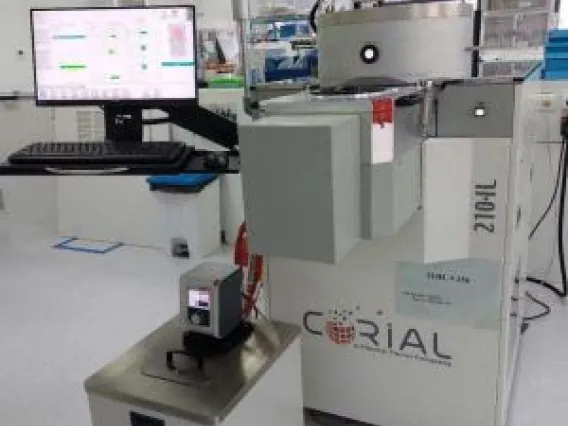

- Micro/Nano Fabrication Center

- Translational Bioimaging Resource

- University of Arizona Genetics Core

- BIO5 Genetically Engineered Mouse Models (GEMM) Core

- Arizona Genomics Institute

Chemical Disclosure

When bringing in a chemical into the Nano Fabrication Center, you must provide NFC staff with the following information:

- Quantity needed for project

- MSDS of the chemical as labeled

- Method of disposal

- Point of contact

- Faculty advisor

- Date it will be removed from facility

You must review chemical use and disposal with Greg Book prior to bringing chemicals into the lab. All chemicals not listed on our MSDS must be approved prior to facility entry!

If a chemical is brought into the lab without proper notification, the individual(s) involved will have their laboratory privileges revoked and their faculty advisor notified. Safety must come first!

Nano Fabrication Center Emergency Response Guide

Fire

- Keep Calm

- Leave the area immediately

- Exit the building via evacuation route

- Pull the nearest fire alarm on the way out

- Go to the ECE Building South Entrance emergency gathering point

- Call 911 using any available phone

- Notify your supervisor and an MFC staff member

Liquid Chemical Spill

- Remove affected clothing immediately

- Wash affected body area with plenty of water (eye rinse station, showers)

- Leave the facility

- Seek medical assistance

- Notify your supervisor and an MFC staff member

Gas Chemical Release

- Leave the area immediately

- Exit the building via evacuation route

- Pull the nearest fire alarm on the way out

- Go to the ECE Building South Entrance gathering point

- Call 911 using any available phone

- Notify your supervisor and an MFC staff member

Power Outage

- Keep calm

- Quickly turn off / safe mode critical equipment

- Leave the facility

- Notify your supervisor and an MFC staff member

Facilities Outage

- Call to Report:

Exhaust, CDA, water (non-DI), building heat - Facilities Management: (520) 621-3000

House N2, DI water - MFC Staff (Gregg: (520) 307-0925)

Highly Toxic/Flammable Chemicals in this Facility

- Silane, dichlorosilane, phospine/silane - Contact: Gregg Cure, (520) 626-1987

- HF (anhydrous), chlorine, trimethyl aluminum, titanium tetrachloride - Contact: Anthony Muscat, (520) 626-6580

Safety Training & Keys/Codes

Step 1: Required Safety Training (All Clients)

- Please get your UA "NetID" and your UA email. Please refer to netid.arizona.edu to setup on if you do not have one already. All clients will be issued a "NetID" and password by the University Information Technology Services.

- Using your UA email please send a request to mfc_staff@list.arizona.edu with "Please add me to safety approval #20071 MFC" in the subject line. This request will be reviewed and forwarded for RLSS.

- It may take up to 3 business days for you to receive an email invitation in reply to your request from RLSS-CHEM-SUPPORT. Follow the instructions in the email and accept invitation. If you do not, please feel free to contact rlss-chem-support@email.arizona.edu with a followup email.

- Using your NetID and password please log in to the RLSS User Dashboard and click on "Notifications/Training Required" to view the course. This course typically takes 1.5-2 hours to complete.

Step 2: Required MFC Specific Safety Training (All Clients)

We provide all clients with an overview of safety requirements needed to safely complete their tasks. We are a CSL-3 facility with a number of highly toxic and pyrophoric chemicals required for fabrication stored and used onsite.

Following the successful completion of your online chemical safety course in Step 1, please contact an MFC staff member at mfc_staff@list.arizona.edu to schedule the facility specific one-on-one safety orientation. The training will be scheduled once a week at a time convenient for all requesters for that week.

Prior to your one-on-one safety tour appointment please review the following:

- Authorized users requiring access to the Material Safety Data Sheets (MSDS) may view them via RLSS

- MFC Emergency Response Guide

- Chemical Disclosure

-

MFC Safety Rules

Please print and bring a copy of the MFC Safety Tour Participant Checklist to your appointment. make sure you have reviewed all items and signed the form before leaving after completion of the tour.

Step 3: Keys & Access Code Requirements

Our single access and short term clients (<30 days) will not be issued keys/door access codes, although exceptions could be made. Access will be available M-F 8am-5pm and must be pre-arranged through an MFC staff member. Please email mfc_staff@list.arizona.edu to make arrangements.

Keys and access codes are issued generally only to long term (>30 days) clients:

- A valid CatCard is required to gain access to the building, offices, and laboratories on campus. Industrial clients will be granted a Designated Campus Colleague (DCC) status and issued a CatCard. Please contact an MFC staff member to initiate the process.

- Please download and print the access form and fill it out.

An MFC staff member can help you out the access form if needed. We will need a copy of your valid CatCard. You will then be notified via email when the codes or keys are available for you to pick up in person.

Per university policy, you should never share your keys or codes with anyone. If you believe your keys or codes have been compromised, contact MFC staff immediately.

Safety Requirements

An NFC staff member will conduct a facility specific safety orientation and provide all clients with an overview of safety requirements needed to complete their work in the facility. We are a CSL-3 facility with a number of highly toxic and pyrophoric chemicals required for fabrication stored onsite. Please print and bring a copy of the NFC Safety Orientation Participant Checklist to your appointment.

Prior to your one-on-one safety tour appointment please review link 1 and the summary of rules at link 4 while carefully reviewing the information presented at links 2 and 3 below:

- University of Arizona Chemical Safety Manual*

- Short Video on CO Safety and Detection*

- Pima County Waste Water Ordinance*

Metrology

Ellipsometer, profilometers, 4 pt probe, Filmetrics & Nanospec for thickness. We have access to a number of SEM/EDX facilities on campus.

Metallization

E-beam & thermal evaporation.

RF and DC sputtering.

Pagination

- Previous page

- Page 2

- Next page