LP-III Vapor Prime Oven

The LP III Vapor Prime oven. It is located within the class-100 cleanroom.

The LP III Vapor Prime oven. It is located within the class-100 cleanroom.

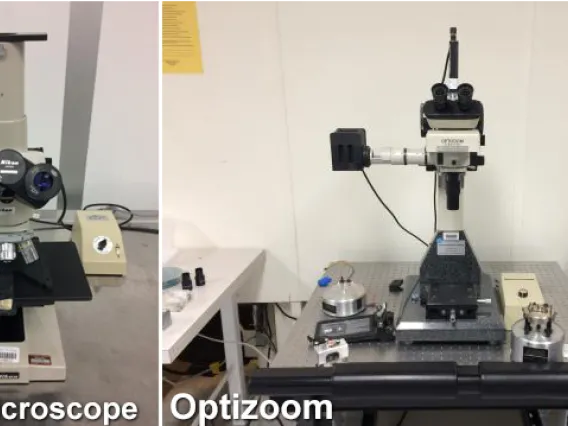

There are a few locations throughout the class 100 cleanroom that you will find microscopes. There is only one location to find the Nikon Optizoom which allows for more advanced magnification. These microscopes are often utilized to analyze the structural integrity of various degrees such as bonds, imperfections, and situational accuracy.

Located in the chase area outside of the cleanroom. Workspace for processing that does not require ventilation. Equipped with a DI water faucet and a DI water hand sprayer.

Exhausted hood located in the cleanroom's lithography area (yellow room). Workspace for working with solvents and other volatiles. Equipped with filtered N2 gun. Space underneath for storage of common solvents and organics, e.g. developers.

Exhausted wet bench located in the cleanroom's lithography area (yellow room) and equipped with filtered lights. Work space for performing chemical processing. Equipped with 2 DI water faucets, a DI water hand sprayer, and a filtered N2 gun. Space for placement of hot plates. Storage space for common acids and bases underneath.

The Kulicke and Soffa 780 dicing saw is a back-end processing tool for cutting wafers or substrates, typically silicon or quartz, into smaller pieces or chips for packaging or further processing.

Some of the features of this tool are:

-----

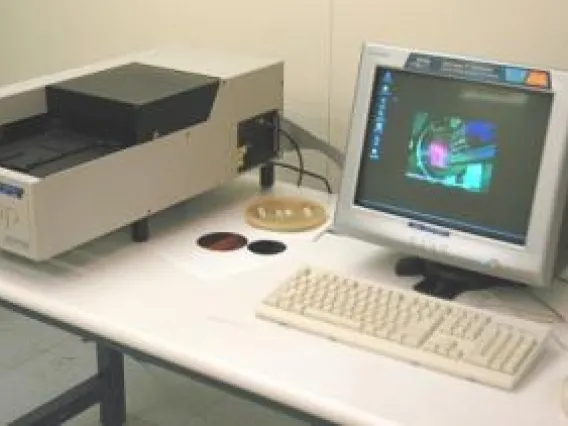

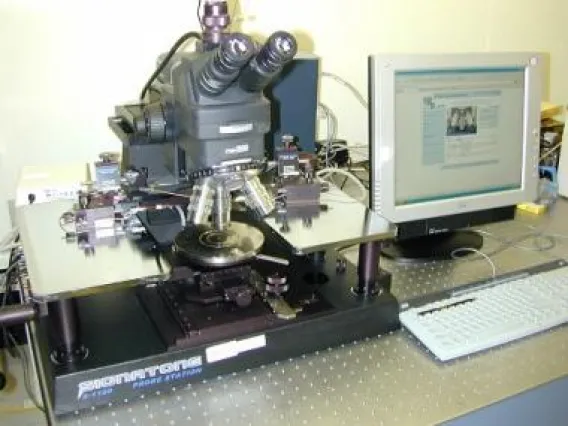

Allows users to view samples and save digital images. Current objectives are 4X, 20X, 40X. Scope can accommodate any size sample and is connected to a computer with internet access. Tool can also be set up for parametric probing of devices.

An advanced profilometer capable of measuring surface morphology and film thickness as large as 200mm.

The CDE Resmap measures and displays thin-film resistivity, sheet resistance, and film thickness. Creates printable and exportable files and substrate apps.